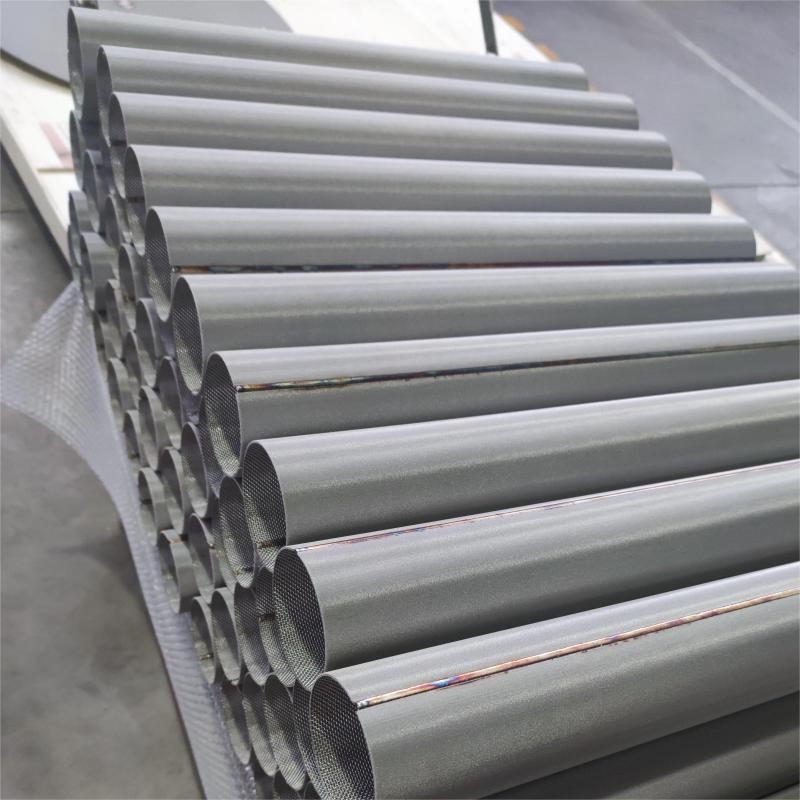

Ulwakhiwo

Umzekelo omnye

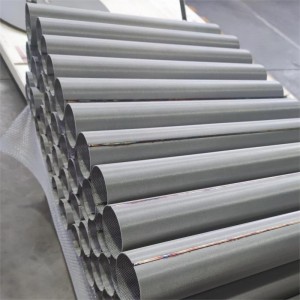

Umzekelo wesibini

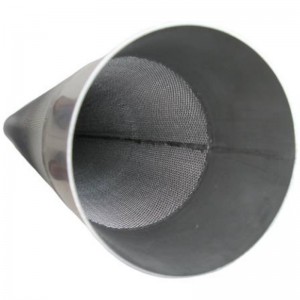

Ezimbini okanye eziNtathu ezinemesh ezifanayo zifakwe kwisiqwenga

Umzekelo wesithathu

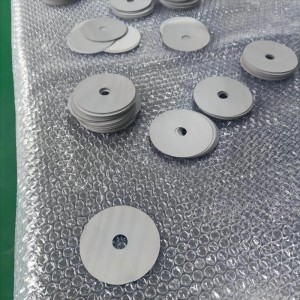

Izinto eziphathekayo

DIN 1.4404/AISI 316L, DIN 1.4539/AISI 904L

Monel, Inconel, Duples steel, Hastelloy alloys

Ezinye izinto ezifumanekayo xa ziceliwe.

Ukulunga kwesihluzi: 1 -200 microns

Iinkcukacha

| Ubalulo-Zimbini okanye ezintathu- umaleko we-sintered mesh | |||||

| Inkcazo | ucolo lokucoca | Ulwakhiwo | Ukutyeba | I-Porosity | Ubunzima |

| μm | mm | % | kg / ㎡ | ||

| I-SSM-T-0.5T | 2-200 | umaleko wesihluzi+80 | 0.5 | 50 | 1 |

| I-SSM-T-1.0T | 20-200 | umaleko wesihluzi+20 | 1 | 55 | 1.8 |

| I-SSM-T-1.8T | 125 | 16+20+24/110 | 1.83 | 46 | 6.7 |

| I-SSM-T-2.0T | 100-900 | umaleko wesihluzi+10 | 1.5-2.0 | 65 | 2.5-3.6 |

| I-SSM-T-2.5T | 200 | 12/64+64/12+12/64 | 3 | 30 | 11.5 |

| Amagqabantshintshi:Esinye isakhiwo somaleko sifumaneka xa siceliwe | |||||

Usetyenziso

Izinto zokucoca ulwelo, imigangatho yebhedi enamanzi, izinto zokungenisa umoya, imikhonjana yokuhambisa umoya.etc.

Ukuchaneka kokucoca kwe-mesh yensimbi engenasici sintered cylindrical filter element ingaphezulu kwe-0.5 ~ 200um.

I-sintered steel stainless steel mesh cylindrical filter element ineempawu zokuchaneka okuphezulu, ukunyanzeliswa okulungileyo, amandla aphezulu, ukuxhathisa okuqinileyo kwe-corrosion, ukucocwa lula kunye nokucoca ngasemva, akukho lula ukonakalisa, kwaye akukho kwahlulwa kwezinto.

Umnatha wensimbi engenastainless sintered cylindrical filter element isetyenziswa ikakhulu ukuhluza ipolyester, iimveliso zeoyile, amayeza, ukutya nesiselo, iimveliso zekhemikhali, kunye nokuhluza imithombo yeendaba efana namanzi nomoya.

Intsimbi engenastainless mesh sintered cylindrical filter elements igubungela uluhlu olubanzi lobungakanani kunye neenkcukacha.Zonke iinkcukacha zobungakanani zinokuyilwa kwaye ziveliswe ngokweemfuno zabathengi, kwaye iimveliso ezifanelekileyo zinokuyilwa kwaye zinconywe ngokweemeko zokusebenza kunye neemfuno.

Izinto eziphathekayo: insimbi engenasici ye-SUS304, i-SUS316L, njl., insimbi engenasici: iMonel, i-Hastelloy, njl.

Ezona zibonelelo ziphambili ezilishumi elinambini kunye neempawu zomnatha wentsimbi engatyiwa sintered cylindrical filter element yoluhlu lwesihluzo sentsimbi engenastainless zezi zilandelayo:

1. Itekhnoloji yokuhluza yamkela i-welding ye-vacuum ye-high-precision ephezulu, kunye nenkqubo yobugcisa esemgangathweni (siya kuqhubeka nokuvelisa izinto ezintsha kunye nokuphuhlisa, kwaye kuya kubakho iteknoloji yokucoca i-ultra-precision ukukhonza ihlabathi kwixesha elizayo);

2. Uluhlu oluchanekileyo lwangoku: ukusuka kwi-0.5 ukuya kwi-200 microns nangaphezulu, kunye noluhlu olubanzi lokuchaneka okusebenzayo;

3. Amandla omatshini aphezulu, ukuqina okulungileyo kunye nokuchaneka okuzinzile kakhulu.Ukusebenza kokumelana noxinzelelo oluphezulu kugqwese kakhulu, ngakumbi kufanelekile kwizihlandlo ezifuna amandla aphezulu oxinzelelo kunye nobukhulu becala lokucoca okufanayo;

4. I-impedance yokucoca okuphantsi kunye nokungena kakuhle kakhulu;

5. Izinto eziphathekayo zikumgangatho ophezulu wokucoceka kokutya kwibakala lensimbi engenasici, enokumelana nokunxiba kakuhle kakhulu;

6. Eyayidala ubuchwephesha behlabathi bokuchaneka obuphambili, into yokucoca igudile kwaye kulula ukuyicoca, ngaphandle kokuwa kwezinto;

7. Ukumelana nokubanda kuhle kakhulu, kwaye ubushushu obuphantsi bunokufikelela ngaphantsi kwe-220 degrees (ubushushu obukhethekileyo be-ultra-low bungenziwa ngokwezifiso);

8. Ukumelana nobushushu kuhle kakhulu, kwaye ubushushu bokusebenza bunokufikelela ngaphezu kwama-650 degrees (ubushushu obukhethekileyo be-ultra-high bungenziwa ngokwezifiso);

9. Ukumelana neendawo zokusebenza ezifana ne-alkali eyomeleleyo kunye ne-asidi eqinile;

10. Umatshini wokuhluza ukucoca umphezulu, kwaye umjelo we-mesh ugudileyo, ngoko unomsebenzi obalaseleyo wokuhlaziya umva kwaye unokusetyenziswa ngokuphindaphindiweyo ixesha elide, ngokukodwa ukulungeleka kweenkqubo zokusebenza eziqhubekayo kunye ezizenzekelayo, ezingahambelani nayo nayiphi na into yokucoca. ;

11. Umda wesicelo ubanzi kakhulu, ufanelekile kwiigesi ezahlukeneyo, ulwelo, izinto eziqinileyo, amaza omsindo, ukukhanya, ubungqina bokuqhuma, njl njl. (iindlela zokudibanisa eziphambili: ujongano oluqhelekileyo,, uxhulumaniso olukhawulezayo lwe-interface, uxhumano lwe-screw, uxhulumaniso lwe-French Lan, uxhumano lwentonga yokubopha, ujongano olukhethekileyo lwesiko, njl.);

12. Ukusebenza ngokubanzi ngokucacileyo kuphezulu kunezinye iintlobo zezixhobo zokucoca ezifana ne-sintered powder, i-ceramics, i-fiber, i-cloth yokucoca, iphepha lokucoca, njl.