Ulwakhiwo

Izixhobo

I-Din 1.4404 / Aisi 316l, Din 1.4539 / Aisi 904l

Imoda, i-intelnel, i-Deles Steel, i-Dotelloy Altels

Ezinye izixhobo ezifumanekayo ngesicelo.

Ukuhlekisa kwecebo lokucoca: 1 -200 microns

Inkcazo

| Ukucaciswa-punching plate wire mesh mesh | ||||

| Inkcazo | Ukucocwa komzimba | Ulwakhiwo | Ubukhulu | Ukuthambisa |

| μm | mm | % | ||

| I-SSM-P-1.5t | I-2-100 | 60 + 60 ungqimba ungqimba + 60 + 30 + φ4x5px1.0t | 1.5 | 57 |

| I-SSM-P-2.0t | I-2-100 | 30 + 30 Ubume bokuhluza + 30 + φ5x7px1.5t | 2 | 50 |

| I-SSM-P-2.5T | I-20-100 | 60 + 60 ungqimba ungqimba + 60 + 30 + φ4x5px1.5t | 2.5 | 35 |

| I-SSM-P-3.0T | I-2-200 | 60 + ungqimba ungqimba + 60 + 20 + φ6x8pgx2.0t | 3 | 35 |

| I-SSM-P-4.0T | I-2-200 | 30 + 30 Umaleko wecebo + 30 + 20 + φ8x10ptx2.5t | 4 | 50 |

| I-SSM-P-5.0T | I-2-200 | 30 + + ungqimba lomoya + 30 + 20 + 16 + 10 + φ8x10ptX3.0t | 5 | 55 |

| I-SSM-P-6.0T | 2-250 | 30 + + ungqimba lwefilo + + 20 + 20 + 10 + 10 + φ8x10ptx4.0t | 6 | 50 |

| I-SSM-P-7.0T | 2-250 | 30 + + ungqimba ungqimba + 30 + 20 + 16 + 10 + φ8x10ptx5.0t | 7 | 50 |

| I-SSM-P-8.0T | 2-250 | 30 + + ungqimba lwefilo + + 20 + 20 + 10 + 10 + φ8x10ptX6.0t | 8 | 50 |

| Ubungqingqwa beplate yokutyibilika kunye nemo ye-mesh ye-wire mesh inokwenziwa ngokwezifiso ngokweemfuno zomsebenzisi. | ||||

Amagqabantshintshi, ukuba isetyenziswa kwi-filters yokucoca i-filter yokuhlamba i-sliters, isakhiwo seplate yefiltha sinokuba ngumgangatho wesihlanu kunye neplate ephambeneyo.

Leyo yi-100 + 100 + yomaleko wecebo + 100 + i-12/64 + 64 + 64 + 124 + 12 + 4.0T

Ubungqingqwa beplate yokuPhila buxhomekeke kwimfuno yakho yoxinzelelo.

Le mveliso ilungele indawo ePhakamileyo yoLoxinzelelo okanye imfuneko ephakamileyo yangasemva, isombulule ngokufanelekileyo imveliso yokuqhubeka kweshishini le-PHEMOCOOCATICAL kunye ne-Chemical kunye ne-intanethi, iimfuno zemveliso ezingeyongozi.

Izicelo

Ukutya kunye neXesha, unyango lwamanzi, ukususa uthuli, ikhemisi, iikhemikhali, i-polymer, njl.

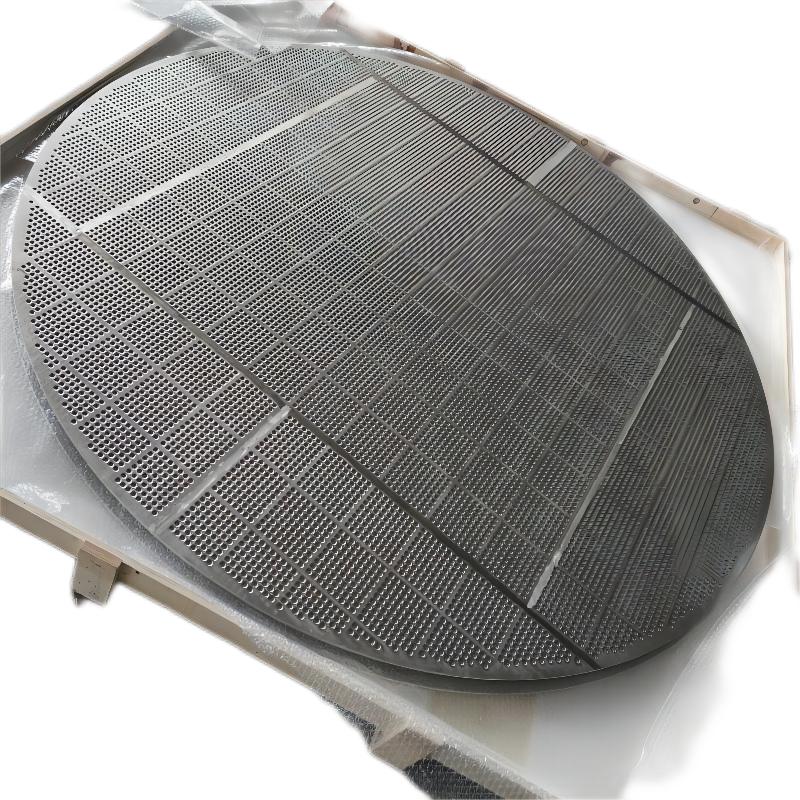

Iplate yeplate efakwekeleyo ye-mesh luhlobo lwe-mesh ene-mesh enezinqwaba ipleyiti kunye ne-mesh evuthayo. Iplate yokutyibilika inokukhethwa kubungakanani bahlukeneyo ngokweemfuno, kwaye i-Net i-Net inokuthi ibe yinye okanye ngaphezulu. Ngenxa yeplate yokuphosela njengenkxaso, i-mesh ye-mesh inamandla aphezulu ecinezelayo kunye namandla oomatshini. Ukuqina kokubini akunayo kuphela umoya ofanelekileyo wokufana noMesh, kodwa unamandla omatshini weplate enkulu. Ingaqwalaselwa ukuba ibe yi-cylindrical, i-disc, iphepha kunye neefilitha zeCone, isetyenziswe ngokubanzi kunyango lwamanzi, isiselo, ukutya, i-metallgergy, amachiza amayeza, njl.

Ipleyiti yeplate efakiweyo ye-mesh:

(1) Ubungqola obuhle kunye namandla aphezulu omendo. Ngenxa yenkxaso yeplate yokugweba, inamandla amakhulu omatshini kunye namandla ecinezelayo phakathi kwemithi etywilekileyo;

.

(3) Kulula ukucoca, isihluzi somphezulu samkelwe, ngakumbi silungele ukusela umva;

.

.

Ipleyiti ye-prefayitha isebenza:

(1) Izixhobo ezisetyenziselwa ukupholisa ukupholisa kwiindawo ezingamaqondo obushushu kakhulu.

.

.

(4) Isetyenziselwa ukuqhuma kwefleting

(5) Ukuqulunqa, ukuhlamba kunye nokoma kwezixhobo kwishishini lamayeza.

(6) Inkxaso ye-Catalyst ye-Grille.

.