Ulwakhiwo

Izinto eziphathekayo

DIN 1.4404/AISI 316L, DIN 1.4539/AISI 904L

Monel, Inconel, Duples steel, Hastelloy alloys

Ezinye izinto ezifumanekayo xa ziceliwe.

Ukulunga kwesihluzi: 1 -200 microns

Iinkcukacha

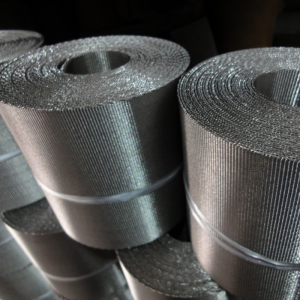

| Ubalulo-Ipleyiti yokubethela i-sintered wire mesh | ||||

| Inkcazo | ucolo lokucoca | Ulwakhiwo | Ukutyeba | I-Porosity |

| μm | mm | % | ||

| I-SSM-P-1.5T | 2-100 | 60+ umaleko wesihluzi+60+30+Φ4x5px1.0T | 1.5 | 57 |

| I-SSM-P-2.0T | 2-100 | 30+ umaleko wesihluzi+30+Φ5x7px1.5T | 2 | 50 |

| I-SSM-P-2.5T | 20-100 | 60+ umaleko wesihluzi+60+30+Φ4x5px1.5T | 2.5 | 35 |

| I-SSM-P-3.0T | 2-200 | 60+ umaleko wesihluzi+60+20+Φ6x8px2.0T | 3 | 35 |

| I-SSM-P-4.0T | 2-200 | 30+ umaleko wesihluzi+30+20+Φ8x10px2.5T | 4 | 50 |

| I-SSM-P-5.0T | 2-200 | 30+umaleko wesihluzi+30+20+16+10+Φ8x10px3.0T | 5 | 55 |

| I-SSM-P-6.0T | 2-250 | 30+umaleko wesihluzi+30+20+16+10+Φ8x10px4.0T | 6 | 50 |

| I-SSM-P-7.0T | 2-250 | 30+ umaleko wesihluzi+30+20+16+10+Φ8x10px5.0T | 7 | 50 |

| I-SSM-P-8.0T | 2-250 | 30+umaleko wesihluzi+30+20+16+10+Φ8x10px6.0T | 8 | 50 |

| Ubunzima bepleyiti yokubhoboza kunye nesakhiwo se-wire mesh sinokwenziwa ngokwezifiso ngokweemfuno zomsebenzisi. | ||||

Amagqabantshintshi, ukuba isetyenziswe kwi-Multifunctional filter washing dryers, isakhiwo sepleyiti yokucoca inokuba kumgangatho oqhelekileyo we-five-layer kunye ne-punching plate sintered kunye.

Leyo yi-100+ umaleko wesihluzi+100+12/64+64/12+4.0T(okanye Yenye ipleyiti yokungqinga ubukhulu)

Ubukhulu bepleyiti yokubhoboza bukwaxhomekeke kwimfuno yakho yoxinzelelo.

Le mveliso ilungele iimeko zoxinzelelo oluphezulu okanye uxinzelelo oluphezulu lokubuyela umva, ukusombulula ngokufanelekileyo ukuveliswa okuqhubekayo kwemveliso yamayeza kunye neekhemikhali kunye nokuhlanjwa kwe-intanethi, iimfuno zemveliso eziyinyumba.

Usetyenziso

Ukutya & isiselo, unyango lwamanzi, ukususa uthuli, ikhemesti, imichiza, ipolymer, njl.

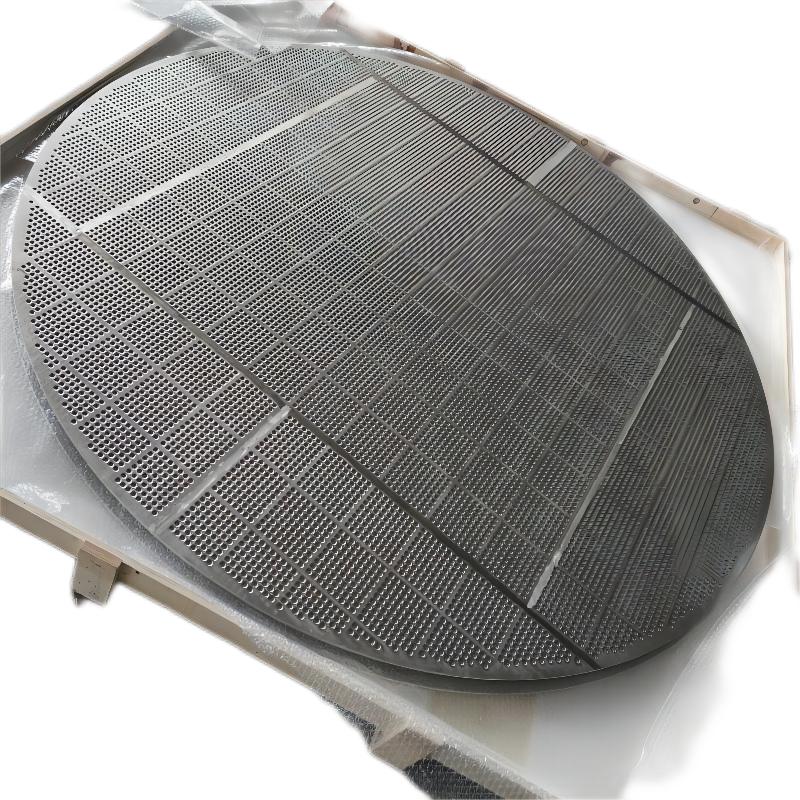

Ipleyiti enemingxuma sintered mesh luhlobo lwe mesh sintered that sinters the porous plate and the base flat iflaty umnatha olukiweyo kunye.Ipleyiti yokubhoboza ingakhethwa kubukhulu obahlukeneyo ngokweemfuno, kwaye umnatha wokuluka unokuba ngomnye okanye ngaphezulu.Ngenxa yepleyiti yokubhoboza njengenkxaso, i-mesh edibeneyo inamandla amakhulu oxinzelelo kunye namandla omatshini.I-sintering yezi zimbini ayinayo kuphela i-air permeability elungileyo ye-flat mesh ephothiweyo, kodwa inamandla omatshini wepleyiti ye-porous.Iyakwazi ukucutshungulwa kwi-cylindrical, i-disc, i-sheet and cone filters, esetyenziswa ngokubanzi kunyango lwamanzi, isiselo, ukutya, i-metallurgy, iikhemikhali kunye namashishini amayeza, njl.

Iimpawu zepleyiti ene-sintered mesh:

(1) Ukuqina okuhle kunye namandla aphezulu omatshini.Ngenxa yenkxaso yepleyiti yokubhoboza, inamandla aphakamileyo omatshini kunye namandla acinezelayo phakathi kwe-meshes ene-sintered;

(2) Ukuchaneka okuphezulu kokucoca, uluhlu lwe-filtration echanekileyo yi-1μ-100μ, kwaye inokusebenza okuthembekileyo kokucoca;

(3) Ukucoca ngokulula, isihluzo somphezulu samkelwe, silungele ngakumbi ukuhlamba umva;

(4) Ayinakukhubazeka ngokulula, imilo ye-mesh ilungisiwe, ubungakanani be-gap bufana, kwaye akukho mngxuma oyimfama.

(5) Ukumelana nokubola, ukumelana nobushushu obuphezulu, kunokumelana nobushushu obuphezulu be-480 ℃.

Ukusetyenziswa kwepleyiti ene-sintered mesh:

(1) Izixhobo ezisetyenziselwa ukupholisa okusasazeka kwindawo yobushushu obuphezulu kakhulu.

(2) Ukusetyenziswa kokufana kwegesi kwishishini lomgubo, iipleyiti ezinolwelo kwishishini lentsimbi.

(3) Imathiriyeli yepleyiti yeOrifice yokuhambisa igesi ibhedi enamanzi.

(4) Isetyenziswa kwinaliti yokuqhushumba yesithando somlilo esivuthulukileyo sokuhamba kwamalahle kunye nenkqubo yokuhambisa inqanaba elishinyeneyo.

(5) Ukuhluzwa, ukuhlanjwa kunye nokomiswa kwezinto kumashishini amayeza.

(6) I-Catalyst support grille.

(7) Isetyenziselwa ukuhluza i-polyester, i-oyile, ukutya kunye nesiselo, iimveliso zemichiza yefiber, kunye nokucocwa kwamanzi kunye nokuhluzwa kwegesi.